Table Of Content

In the meticulous craft of creating a Product Design Specification, certain missteps can lead to project delays or product misalignment. Addressing these early on ensures the integrity of your PDS and the success of your product in the competitive market. Before proceeding from the design phase to actual production, it’s essential to perform a meticulous evaluation of your Product Design Specification. This decisive step guarantees that your PDS stands as a thorough, unambiguous guide, ready to navigate your product through its development journey. Comprehensive cuts across various disciplines within your team are vital. It’s where engineers, marketers, and designers converge to critically assess every clause in the PDS.

Specification (technical standard)

A straightforward and brief PDS (Product Design Specification) encourages teamwork and support among various teams and fields. It gives everyone a common grasp of the project's objectives, needs, and details, making team cooperation more efficient. By cutting down on the need to redo things and avoiding unnecessary back-and-forths, a PDS can save time and resources, making the design process run more smoothly.

From Testing to Launch

Mary has a liberal arts degree from Goddard College andspends her free time reading, cooking, and exploring the great outdoors. Of course, if the chair can be approved for a person being 120[kg] and the packaging dimension of 80x450x450[mm], then the requirements are still met. Stack Exchange network consists of 183 Q&A communities including Stack Overflow, the largest, most trusted online community for developers to learn, share their knowledge, and build their careers. It can be just one or multiple units, but make sure to track that here.

Manually combine design specs into a document

With a vigilant approach to these common pitfalls, your PDS will retain the necessary clarity and flexibility. It will serve as a solid foundation from which your product can evolve, bearing in mind the fine balance between prescriptive details and creative leeway. Consequently, your project moves forward effectively, keeping all teams on the same page and focused on a unified outcome. By seamlessly transitioning through this closing phase, your PDS will transform into a clear and actionable guide, not just for the present development phase but also as a beacon for future product enhancements. In many contexts, particularly software, specifications are needed to avoid errors due to lack of compatibility, for instance, in interoperability issues. Rewisoft team has a wealth of experience in writing such documents, so you can fully rely on us.

In order to correctly write a user requirement document, you must know well those for whom you will design and develop the product. User requirements are statements in natural language with diagrams that describe the services the system is expected to offer to system users as well as the restrictions it must function under. The system design specification examples and software design specification examples you can simply find on the Internet. When you are not professional in product management and have never had to create a design specification before, then you have come to the right place. If the question of what specification means makes you think a lot, this article is written for you. During the designing and making processes it is important to gather feedback from the client and users.

This might be the first time you need to amend the scope you set out based on what you learn. You may need to come back to stakeholders to check if their desires still stand in the light of this new evidence. In fact, if there’s no evidence a problem exists to solve, you may even decide to stop here. Now that you have that shared understanding, you can confirm with certainty whether a problem exists. You can gather evidence by talking to customers, looking over your analytics, and observing how users interact with your product. A product discovery phase is where you define the problem you are looking to solve and confirm it exists before testing ways to solve it.

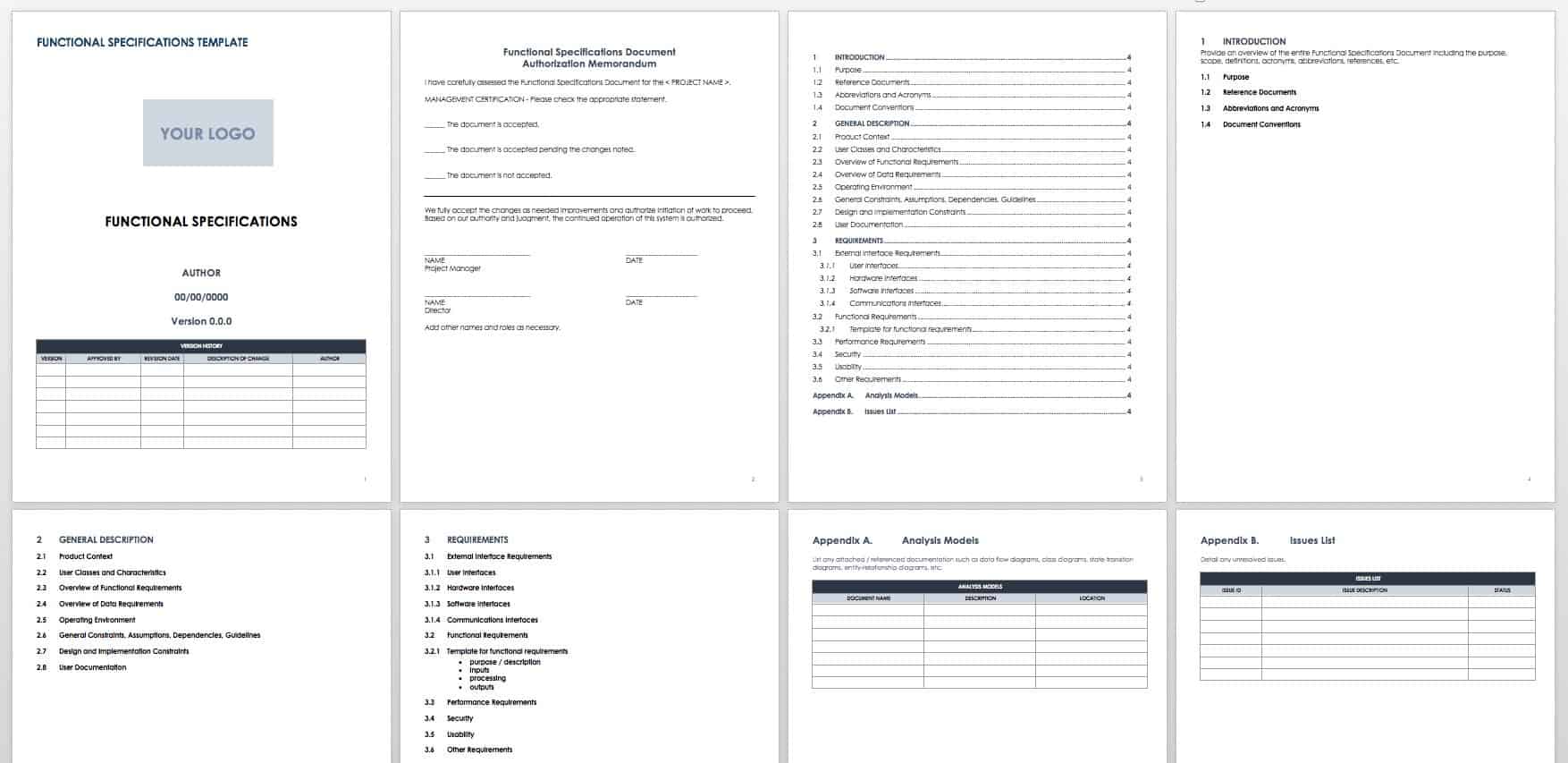

In the UX process, design specs are created at the end of the Design phase. At this time, user expectations for the product are established, the global design goals are clear, and the design is ready for production (engineering and development phase). This is when a designer will hand over the design to a developer for coding (design to development workflow). There are multiple layers of information and details that needs to be conveyed, and it’s critical for designers and developers to be on the same page. Design specs align everyone and are used by developers to implement the design. A technical specification document outlines how you’re going to address a technical problem by designing and building a solution for it.

What is the ideal size for a salon waiting area?

Roof design and specification: the dos and don’ts - Architecture Today

Roof design and specification: the dos and don’ts.

Posted: Tue, 30 Jan 2024 08:00:00 GMT [source]

It will be easier for designers to go through clearly written paragraphs rather than reading a lot of solid text. After conducting a quality business analysis, you can start writing the design specifications. We have prepared a plan, which can be a little cheat sheet for you when writing design specifications. The design specification will also include a detailed description of the specifications, including dimensions, weight, overall cost, and so forth. It should discuss laden and empty weights as well as any other topics that may be relevant.

Their expertise enables them to spot potential oversights and interject with actionable revisions, ensuring every facet of the product is viable and ready for the challenges of implementation. In (hardware, software, or enterprise) systems development, an architectural specification is the set of documentation that describes the structure, behavior, and more views of that system. A formal specification is a mathematical description of software or hardware that may be used to develop an implementation. It describes what the system should do, not (necessarily) how the system should do it. Given such a specification, it is possible to use formal verification techniques to demonstrate that a candidate system design is correct with respect to that specification. This has the advantage that incorrect candidate system designs can be revised before a major investment has been made in actually implementing the design.

In this section, the PDS must articulate the product’s capabilities, operational benchmarks, and the technological specifications driving it. These parameters provide a clear direction for design and engineering teams as they navigate the myriad of possible product iterations. Although specifications are usually issued by the architect's office, specification writing itself is undertaken by the architect and the various engineers or by specialist specification writers. Specification writers may be separate entities such as sub-contractors or they may be employees of architects, engineers, or construction management companies. In addition, specifications can be "closed" with a specific list of products, or "open" allowing for substitutions made by the constructor. Non-disclosure agreements are a legal framework that protects sensitive and secret information from being made public by the person who receives it.

Tear sheets, on the other hand, are different from cut and spec sheets. While an interior design specification sheet lists all the products and items that will be used in your design, a tear sheet focuses on just one item at a time. A typical tear sheet will include a larger photo of the product or item along with key information, such as the brand name, price, and dimensions or measurements. Tear sheets are used to share visuals of your product and item selections with your clients, while spec sheets are typically used for drafting drawings and ordering products. Check out How to Make an Interior Design Tear Sheet + Template to learn more.

No comments:

Post a Comment